Products

Shop Online

Shopping Cart

Shop Online with Kenani Estate Co Ltd

Kakala Polynesian Body Oil's are distributed by Kenani Estate Co Ltd. Made from virgin coconut oil and fragrance.

Kenani Estate Co Ltd and Kakala Polynesian Body Oils won first prize for "Best Packaging and Best Labeling" in the manufacturing sector for Tongan Made products at the 2013 Royal Agricultural Show. They also won first prize for the "Best Stall and Display" in the manufacturing sector.

Kenani have also started producing delicious coconut oil based sugar scrubs as well as body balms and moisturizers from bases such as coconut oil and candle nut (tui tui).

Read More

The Making of Kakala Polynesian Body Oils

S

The cracked coconuts are discarded and the pre-selected fully mature, husked coconuts are then split into half cups and ready for scraping & grating.

The freshly scraped kernel is weighed and squeezed with manual pressing to get the coconut milk.

The oil is allowed to settle by gravity for a minimum of seven days (the longer the better). The oil coming out of the manual presser has entrained fine particles of dried kernel. These are removed by allowing the oil to clarify by letting it settle for at least two weeks.The resulting oils are combined with water and allowed to ferment, which produces three layers: a protein layer on top, the desirable coconut oil in the middle, and the water at the bottom.

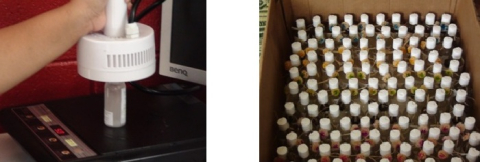

The perched particles are floating on the surface of the oil. They are removed by a simple filtration using of a fine filter bag that will only allow the passage of liquid. This is completed three times for a pure clean result. This process does not leave any unpleasant remainder at the bottom of the bottle after it is packed and left on the shelf for some time. After settling, filtration of the oil is done using a filtering cloth bag.

The oils, after settling for seven or more days are filtered to extract the small particles and to make the oil looking pure and clean.

This process is repeated four times to clarify the oil.Finally the oil has the natural essence fragrance added and is then filled into bottles, sealed and labelled ready to sell.